The human body is a complex system comprised of various interconnected components, including tendons, ligaments, arteries and veins. Much like stretching materials, these biological structures exhibit both elastic and plastic behaviors when subjected to external forces. Understanding the effects of stretching on materials can provide valuable insights into the temporary and permanent changes that occur within tendons, ligaments, and even fluid-carrying arteries and veins.

When a rubber tube or a coiled spring is stretched beyond its elastic limit, it enters a plastic state, resulting in permanent deformation. This alteration occurs due to the breaking and rearrangement of chemical bonds within the material, causing a change in its structure. Similarly, tendons and ligaments in the human body can be stretched beyond their elastic limits, resulting in permanent damage and loss of function.

Stretching a rubber tube or permanently altering its shape can significantly impact flow dynamics. Changes in the material's cross-sectional area can affect the flow rate, with narrower sections causing increased fluid velocity and potential pressure changes, and wider sections leading to decreased fluid velocity. Surface roughness introduces irregularities that disrupt fluid flow, causing increased frictional resistance, turbulence, and changes in flow patterns. Altering the geometry of the tube can create flow restrictions, eddies, and vortices, further affecting pressure distribution and overall flow.

Drawing parallels between permanently stretching a rubber tube and human arteries and veins highlight the impact of flow dynamics in both scenarios. Altered cross-sectional areas in arteries and veins can influence fluid velocity and pressure changes. Surface irregularities due to pathological changes or plaque buildup disrupt smooth flow, increasing frictional resistance and turbulence. Changes in artery geometry, such as bends or constrictions, create flow restrictions, eddies, and vortices, affecting pressure variations and flow patterns.

In engineering systems, poor material compliance can lead to inefficient flow and increased pressure on pumps (think high blood pressure). Flow restrictions, blockages, and turbulence caused by non-compliant materials can impede fluid movement, forcing pumps to work harder to overcome resistance and maintain desired flow rates. This increased pressure places additional strain on pumps, resulting in higher energy consumption, reduced pump lifespan, and potential system failures. Ensuring good material compliance is crucial to prevent excessive pressure and maintain overall system efficiency.

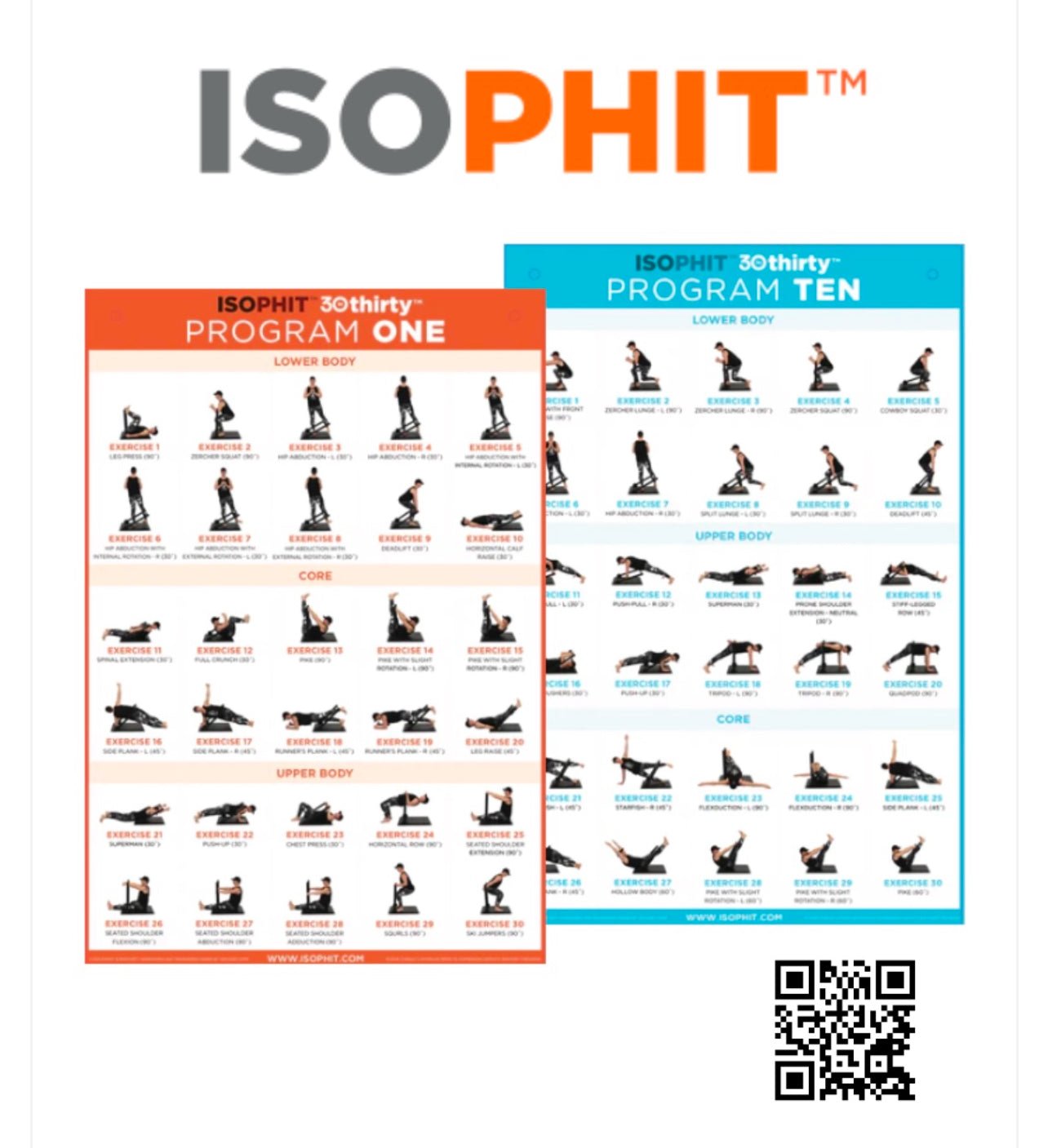

The effects of stretching materials, whether temporary or permanent, have significant implications for tendons, ligaments, and flow dynamics. Understanding the consequences of stretching on these structures provides valuable insights into injury prevention, treatment, and the optimization of fluid-carrying systems. By considering the impact of stretching on both biological and engineered materials, we can enhance our understanding of the complex interactions within the human body and develop more effective strategies like isometric strength training with Isophit for maintaining structural integrity and flow efficiency.

Huge shoutout goes to Isophit family member Greg Moulton. Greg is the founder of Matrix of Motion in Newmarket Ontario Canada.

If you have any questions regarding the article or would like to learn more about Isophit and its benefits for improving functional health and performance, please feel free to email me at brad@isophit.com.

Yours in Isometric Strength,

Brad Thorpe

CEO / Inventor

Isophit

Share:

Isophit: The Champion of Knee Function and Alignment.

Isophit: Is It Time to Change Your Employee Wellness Strategy?